go to WEEK 8 Online Course Support

MSE 5090: Case Studies in Material Selection

Week 8 - Midterm Review

Example Problems - Solutions

- Eating Utensils - Ranking

- Eating Utensils - Fracture Toughness

- Case for Notebook Computer - Shaping

- Processing Methods

- Problems

Eating Utensils - Ranking

As given in the problem:(I) Objective function:

(II) For stiffness consideration:

Since stiffness is proportional to the reciprocal of deflection

one can consider

instead of stiffness.

The maximum deflection allowed in the problem

is given in the "useful solution A3":

Substitute I with

listed in the given table:

Substitute the only free variable t in the objective function :

The energy content Q can be minimized by maximizing the performance index

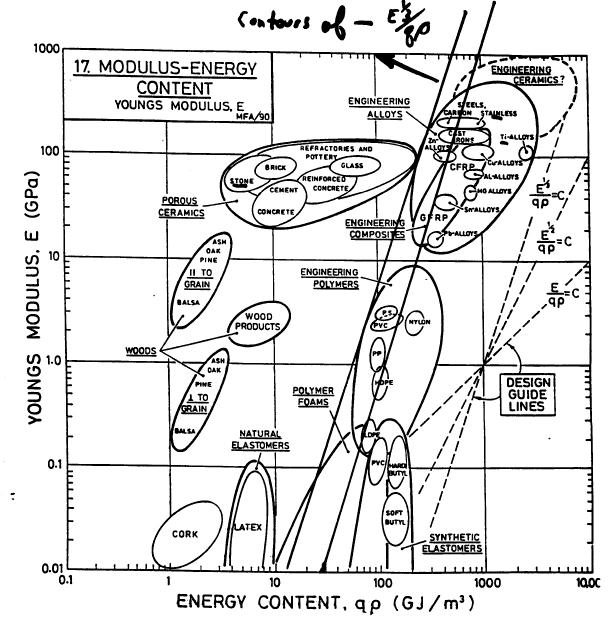

By using Chart 17, one can draw the conclusion:

Qstone < Qstainless steel < QTi alloys (III) For strength consideration:

The failure force Ff is given in the "useful solution A4" as:Substitutewith

as listed in given table

Substitute the only free variable t in the objective function:

The energy content Q can be minimized by maximizing the performance index:

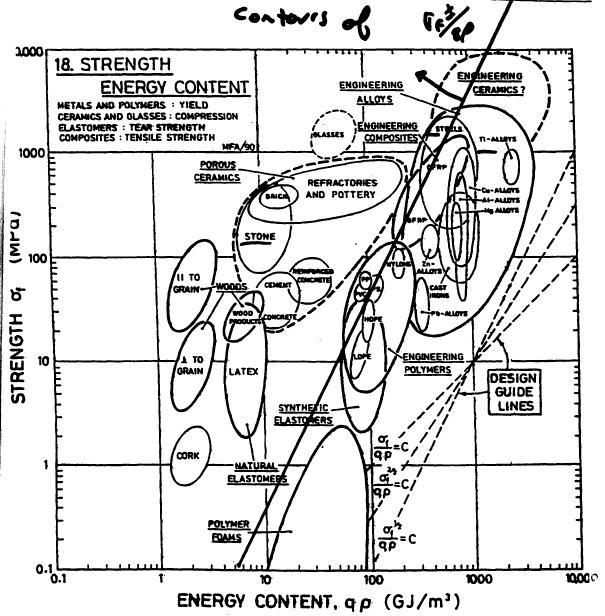

By using Chart 18, one can draw the conclusion:

Qstone < Qstainless steel < QTi alloys

Eating Utensils - Fracture Toughness

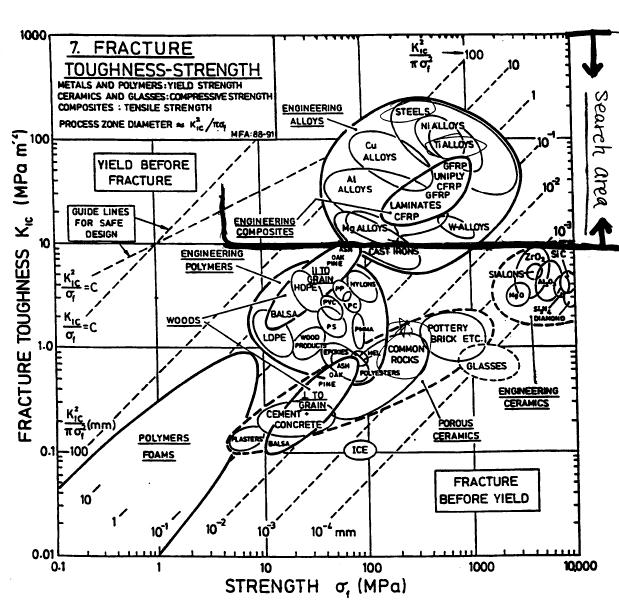

By using Chart 7, one knows that stones (natural) have a facture tougness kic less than 10 Mpa m½. So these manufactures are not going to take the order from you for those stone eating utensils. On the other hand, they will prefer stainless steel, which has a higher kic than that of Ti alloys.

Case for Notebook Computer - Shaping

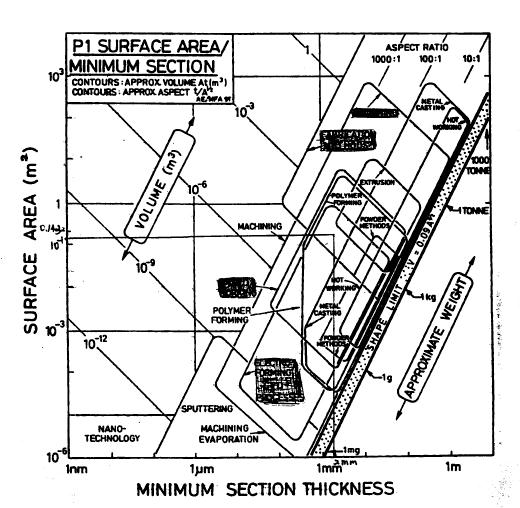

According to the problem, the outer dimensions of both base and lid will be 280x220x10mm, so the total surface area A is calculated as below:A = 2(280×220) + 4(280×10) + 4(220×10) = 1.432×105mm2 = 0.1432m2

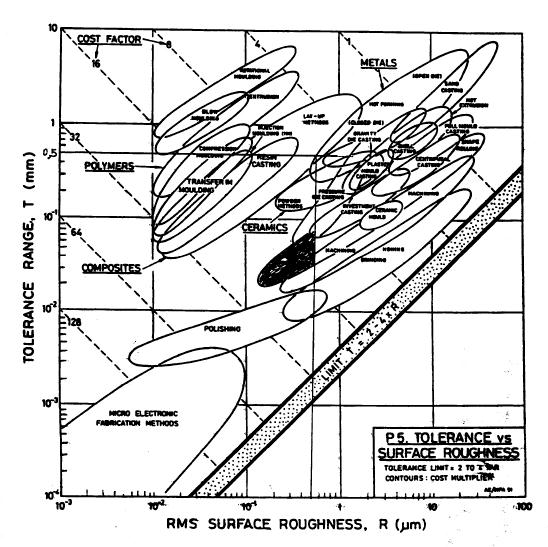

while t = 2mmBy using Chart P1, on knows that there are four possible ways to shape the case:

1) Machining 2) Fabrication methods 3) Cold working 3) Electroforming, CVD-process But considering the raw materials is thin Al sheets, one should quickly pick up cold working (cold die forging) as the best way to shape the case. Checking in Chard P5, cold working can certainly meet the tolerance requirement, and somehow meet the requuirement of RMS surface roughness. (If not, further polishing proecedure is required.)

Processing Methods

There are ten products listed bellow, please find the proper processing methods from the choices provided. (Fill the letters of processing methods into the brackets.)

Products: Processing methods: (1) Coins ( d ) ( a ) Cold rolling (2) Turbine blades ( c ) ( b ) Hot rolling (3) Telephone receiver ( f ) ( c ) Powder metallurgy (4) Metal welded pipe ( b ) ( d ) Die forging (5) Tires ( g ) ( e ) Slip casting (6) Steel auto body panels ( a ) ( f ) Injection molding (7) Ceramic plumbing ware ( e ) ( g ) Compression molding (8) Plastic football ( i ) ( h ) Extrusion (blow molding) (9) Composite gulf club ( j ) ( i ) Rotational molding (10) Plastic milk bottle ( h ) ( j ) Pultrusion

Last update 10-18-98